Showcase 1: Hollow Lignin nanospheres used for drug delivery

Organic nanotechnology can be based on all types of carbon materials. Lignin being an aromatic material having multiple phenolic rings in its structure, it was in the beginning supposed that its structure was a main hindrance for efficient use of lignin in such technology. Nowadays these difficulties have been overcome and all types of nanosized bodies can be easily and efficiently produced also with lignin: irregular nanoparticles, but also nanofibers, hollow nanotubes, nanospheres and hollow nanospheres.

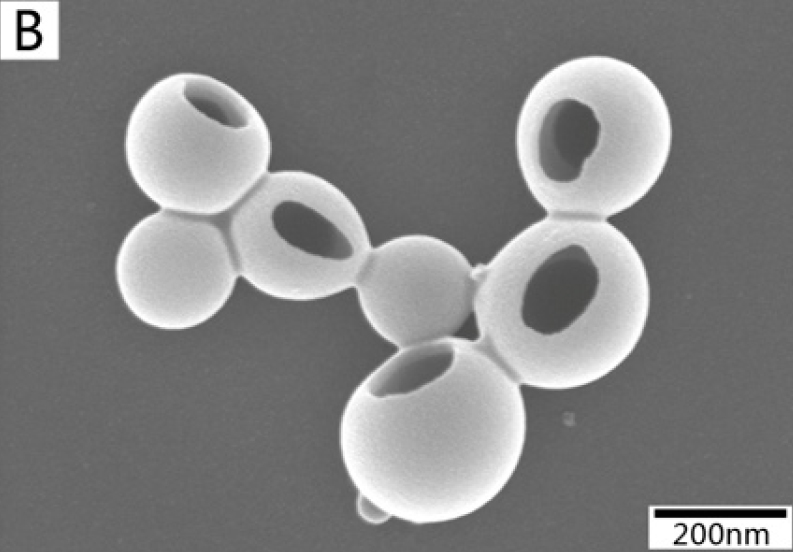

This showcase exhibits a research during which hollow lignin-based nanospheres of a diameter around 200 nm were produced, then charged with an anticancer drug which was successfully released under controlled conditions. Lignin has better biocompatibility than many other possible carrier substances. In the work, it was shown that lignin has no cell-toxicity (the so-called cytotoxicity).

However, it was not pure lignin that was used in this research. In order to attract and fix the anti-cancer drug inside the lignin spheres it was necessary to graft another molecule, β-cyclodextrin, on the lignin prior to the formation of the nanospheres. There grafted molecules improved also the properties, like surface area and pore volume, of the so produced nanoparticles by about 25%.

The principle for producing such nanospheres is very simple. Lignin is first dissolved in THF (Tetrahydrofuran) a very current organic solvent. The desired nanoparticles form when water is added under very specific conditions and creates a precipitate that has the wanted nanostructure, in this case a hollow spherical particle. It is all very simple technology.

The nanospheres could be charged with up to 25% of the anticancer drug. The release was triggered by the pH of the tumor or intracellular microenvironment (pH: 5.5) as well as a physiological (pH: 7.4) environment. Release rates of up to 62% over 60 hours were obtained.

By this research, not only the feasibility of production of hollow nanospheres was demonstrated but in the same time an application of those for controlled release of an anticancer drug under body typical conditions was validated.

Read moreShowcase 2: 50-100% phenol replacement in phenolic resins

The incorporation of lignin into phenolic resins has become increasingly popular in recent years as a sustainable and eco-friendly alternative. Lignin, with its phenolic structure, is a promising raw material for the production of phenol-formaldehyde resins. This integration offers several benefits, making it an attractive option for enhancing the properties of phenolic resins. By substituting a portion of fossil-derived phenol with lignin, this approach can help reduce the environmental impact of phenolic resin production. Additionally, lignin can reduce formaldehyde emissions during both the manufacturing process and throughout the lifespan of products such as wood panels. The inclusion of lignin also improves the thermal stability, flame retardancy, and mechanical properties of the resins. From an economic standpoint, using lignin can lower production costs and reduce dependency on the fluctuating prices of phenol.

The most common applications of lignin-enhanced phenolic resins are in wood adhesives, particularly in products like plywood and oriented strand board (OSB), as well as in high-pressure laminates. However, lignin’s high molecular weight and steric hindrance reduce its reactivity toward formaldehyde compared to pure phenol. To overcome this limitation, lignin typically replaces only part of the phenol content in the resin. In its untreated form, lignin can replace between 20-50% of the phenol, depending on the type of resin and its intended application.

Recent advances in lignin modification have enabled higher replacement rates, with some processes achieving 50-100% phenol replacement. One approach involves thermally treating lignin (at temperatures of 200-250°C) to increase its reactivity. This process involves heating lignin at elevated temperatures, leading to significant chemical changes such as demethylation and demethoxylation. These modifications enhance the reactivity of the lignin, allowing for higher phenol substitution levels, regardless of the wood species used, with potential phenol replacement rates ranging from 50-70%. This process also facilitates the use of hardwood lignin in substantial quantities within phenolic resins. Another method involves treating lignin under alkaline conditions at 75-95°C, which has been implemented on an industrial scale in several countries, achieving up to 60% phenol replacement. The same company claims to have a process with a 100% replacement rate that can be industrialized without issues. Furthermore, advancements made by another party have led to a process capable of replacing 90% of phenol with lignin in commercial applications.

These innovations highlight the potential of lignin as a renewable and sustainable alternative in the production of phenolic resins, making them more eco-friendly and cost-effective.

Extensive evaluation report on this topic

Showcase 3: High-performance concrete dispersants

Dispersants are widely used across various industries to suspend colloidal particles, enhancing the stability of mixtures. Their applications span from cosmetics and paints to pharmaceuticals, oil drilling mud, concrete, and ceramics. These dispersants are essential in many processes, providing improved flow properties, stability, and performance. Recently, a new alkali-oxygen oxidation process has been developed to convert technical lignins into highly effective dispersants, offering a cost-efficient and environmentally friendly alternative to traditional synthetic dispersants.

This novel process involves oxidizing lignin with a combination of alkali and oxygen in a controlled environment, activating the phenolic hydroxyl groups within the lignin polymer and introducing carboxylic acid groups. This modification preserves the integrity of the lignin’s polymeric structure while enhancing its dispersant properties. Depending on the conditions of the oxidation process, particularly the pH level, the lignin’s negative charge and molar mass can be controlled, allowing for the fine-tuning of its dispersing capabilities. The dispersion effect is thought to occur through adsorption onto particles, leading to electrostatic repulsion, which helps maintain the suspension of particles in various systems, such as concrete mixtures.

In the process, lignin is first dissolved in sodium hydroxide (NaOH) at a concentration of about 15% by weight. The solution is then heated to around 70°C, and the reactor is pressurized with oxygen. The reaction typically takes 30 minutes under efficient mixing, during which NaOH is continuously added to counteract the pH drop caused by the acidic byproducts and to accelerate the formation of anionic charges in the lignin. This allows for the creation of an effective lignin-based dispersant that is easily integrated into various industrial applications.

When compared to commercial superplasticizers, the performance of lignin-based dispersants produced through this oxidation process is promising. In tests with concrete mixtures, commercial polycarboxylate ether (PCE) achieved a mortar flow of 220 mm, setting a high benchmark. Other acrylic-based superplasticizers showed less effectiveness, with mortar spreads of only 200 mm and 195 mm. The sulfonated naphthalene-based superplasticizer (SNF) yielded an even lower spread at 180 mm. In contrast, the oxidized lignin dispersants demonstrated a strong dispersion effect, nearly matching the performance of the leading PCE formulation. This development suggests that lignin-derived dispersants could offer a competitive, sustainable alternative in concrete plasticization and other industries requiring effective dispersing agents.

Extensive evaluation report on this topic

Showcase 4: Up to 100% carbon black replacement in rubber

Lignin has gained increasing attention as a sustainable additive in rubber formulations. As a byproduct of the paper and bioethanol industries, lignin offers a promising alternative to traditional fillers such as carbon black and silica. However, several challenges must be addressed before its widespread adoption in rubber applications.

One of the primary difficulties in using lignin in rubber is its inherent polarity. This polarity affects its compatibility with rubber matrices, making it difficult to achieve uniform dispersion and adhesion. For these reasons, lignin tends to aggregate, which can lead to inferior mechanical properties in rubber compounds.

Despite these challenges, recent advancements have demonstrated the potential of lignin in rubber applications. Surface modification techniques, such as esterification, oxidation, and grafting with functional groups, have enhanced lignin’s dispersion and interaction with rubber matrices. Furthermore, researchers have explored hybrid filler systems, where lignin is combined with carbon black or silica to optimize performance while maintaining sustainability benefits.

Lignin’s antioxidant properties are another advantage, as they can improve the aging resistance of rubber products. Ongoing research and industrial trials are refining processing techniques to enhance lignin’s compatibility and performance in rubber formulations. With continued innovation, lignin-based rubber could become a viable, eco-friendly alternative for various applications, from tires to flexible coatings and elastomers.

Recently, new lignin products have appeared on the market having good compatibility with rubber and no odor (no volatile organic compounds - VOCs). These products allow for the replacement of carbon black fillers up to 100% without losses in mechanical properties. Another new commercial product enables the replacement of antioxidants with lignin. For this purpose, a low percentage of carbon black or silica filler is replaced by lignin. This allows for the stabilization of rubber without the need to add traditional antioxidants, which are ecologically questionable.

Extensive evaluation report on this topic

Showcase 5: Up to 70% polyol replacement in polyurethanes

Polyurethanes (PU) are polymers traditionally synthesized through reactions between polyols and diisocyanates, typically derived from petroleum. However, in recent decades, there has been significant interest in developing biobased PUs as part of efforts towards sustainable development. Lignin, among other renewable precursors, has emerged as a promising candidate due to its unique properties that complement polyurethane versatility. Lignin-based polyurethanes have been proposed for various applications, including elastomers, thermoplastics, adhesives, coatings, and foam formulations.

One area where lignin shows particular promise is in the production of rigid polyurethane foam (RPUF), which finds widespread use in building construction, automobiles, acoustics, machinery, and more. RPUF is especially valued as a lightweight insulation material due to its high insulation performance at minimal thickness and low density.

RPUF is typically synthesized by reacting two liquid components: (a) monomeric 4,4’ diphenylmethane diisocyanate (MDI) or polymeric diphenylmethane diisocyanate (pMDI) containing multiple isocyanate (–NCO) groups, with (b) a polyol blend containing polyols with multiple hydroxyl (–OH) groups. By carefully formulating these constituents along with flame retardants, crosslinkers, catalysts, blowing agents, and surfactants, optimizing the processing method, and controlling the cell microstructure, the resulting mechanical and thermal properties can be tailored to specific applications.

However, the main challenge in utilizing lignin in RPUF is its limited solubility in various polyols. Traditional research efforts have thus been limited to replacing only 20-30% of polyols, even with modified lignins. Bern University of Applied Sciences (BFH) in Biel, Switzerland, has now developed a new process for using lignin that allows up to 70% polyol replacement in RPUF while maintaining acceptable mechanical and thermal properties.

Extensive evaluation report on this topic

Showcase 6: Lignin in cosmetics on the verge of commer-cialization

Lignin is increasingly recognized for its potential in the cosmetic industry. As a natural, renewable, and biodegradable material, it aligns with the growing demand for sustainable and eco-friendly beauty products. Among its many functional properties, antioxidant, antimicrobial, UV-blocking, and emulsifying capabilities make it particularly valuable for skincare formulations.

The most advanced and promising application of lignin in cosmetics is as a UV-blocking agent in sunscreens. Due to its strong ability to absorb ultraviolet (UV) radiation, lignin serves as a natural alternative to traditional UV filters, many of which face increasing scrutiny for their potential environmental and health impacts. Lignin can be used alone or in combination with conventional UV absorbers, enhancing photo-stability and prolonging the effectiveness of sunscreen formulations.

Beyond sun protection, lignin’s antioxidant properties make it highly beneficial in anti-aging and protective skincare. Its phenolic structure allows it to effectively neutralize free radicals, thereby reducing oxidative stress and helping to maintain skin health, elasticity, and overall appearance. Additionally, its antimicrobial properties have been explored for acne treatments and cosmetic preservation, as lignin has been shown to inhibit bacterial and fungal growth. This feature not only contributes to improving skin health but also helps extend the shelf life of cosmetic products, reducing the need for synthetic preservatives.

Another key function of lignin is its emulsifying capability. Its amphiphilic nature allows it to stabilize oil-in-water emulsions, making it a valuable ingredient in lotions, creams, and serums. By reducing reliance on synthetic emulsifiers, lignin further supports the shift toward natural and sustainable cosmetics.

Recently, this field of lignin applications has been marked by the fact that several companies are on the verge of commercialization, focusing primarily on lignin-based sunscreens. This marks a significant breakthrough, bringing lignin closer to becoming a mainstream cosmetic ingredient. With its multifunctional properties, strong environmental profile, and growing industrial interest, lignin is poised to play a key role in the next generation of cosmetic products.

Showcase 7: Lignin-based fungicide carrier based on nano-technology goes commercial

For grapevines and other woody plants sicknesses caused by fungi, bacteria and viruses are a global challenge that leads increasingly to important economic losses. An example is the Esca-sickness in grapevines which is caused by a complex of wood-destroying fungi. Esca-fungi enter the plant through wounds created by the cutting of the vines. The fungi penetrate the vascular system of the plants and destroy the vines from the inside. Presently there is no efficient fungicide with systemic action against Esca. Treatment from the outside by spraying is not effective. Worldwide damage by Esca is estimated to be 1.5 billion USD and is expected to further increase in the coming years because of climate change and the connected increasing stress on plants.

Lignilabs GmbH in Mainz (Germany) has developed a platform technology that can encapsulate various substances in lignin nano- and microparticles. Among other applications like polymer additives and 3D printing, the use of this technology on vine stocks allows treating Esca sickness. In this process, an aqueous suspension of lignin carriers (hollow nanospheres) filled with an adapted fungicide is directly injected into the plant which allows for treatment of the sickness at the place of its origin. The product with the commercial name ESCApe acts instantaneously against Esca-fungi and acts preventively on healthy vines to avoid falling sick of the treated vines. ESCApe is active against a large spectrum of wood-destroying fungi and can potentially also be used against pathogens on fruit trees, shrubs, ornamental plants, or in the forest.

The application of ESCApe takes place by a technology specially developed for this purpose (see picture) in the course of which the ESCApe suspension is injected in minimal dosage (0.8 ml) into a drill hole (Ø 6mm, 35mm long) oblique to the vine trunk. Once injected the product distributes in the plant’s vessels and the lignin is degraded by the enzymes produced by the fungus which liberates the pesticides. The fungus destroys, therefore, itself through its enzymes. In addition to the instantaneous treatment effect, there is also a preventive action of 3 to 5 years. Thanks to lignin and its unique properties applied in a skillful way, the production and the application of ESCApe are therefore completely sustainable, user and environmentally friendly.

Showcase 8: Lignin-based organic flow batteries, a key technology for the energy transition

The energy system is subdivided into generation, distribution and consumption sections. But the crucial forth section is energy storage. Production and consumption are most of the time out of phase. Therefore, an efficient storage of huge quantities of energy is the key point for the energy transition.

A diverse range of stationary applications are needed for onshore and offshore wind parks, for large-scale PV plants, for conventional power station locations, for electromobility providers and for operators of residential districts. Battery systems for ships featuring electric propulsion are developed and sold in the maritime segment. As far as usage is concerned, huge quantity storage is the basis for self-consumption enhancement, demand peak capping, interruption-free power supply, electromobility charging infrastructure and standalone operations.

Close to everyone’s future is the problem of how to charge electrical vehicles. The adoption of electromobility requires the comprehensive provision of charging points. A particular challenge is being able to fast-charge several electric vehicles in parallel, a process that is frequently hindered by existing delivery rates. An organic flow battery makes simultaneous fast-charging feasible.In a battery, during the reduction process the electrolytes gain electrons, while during oxidation they lose electrons. Both chemical reactions have to occur separately from one another in the anode and cathode spaces of the energy converter. During the charging and discharging processes, the electrolytes – posolyte and negolyte – are pumped continuously through the stack’s cells, hence the term “flow”. ”Organic” refers to the fact that the electrolyte is an organic liquid. The most promising technology for that is the one based on lignin which is developed by the German company CMBlu.

Everybody knows lithium batteries which cannot be replaced by organic flow batteries at small scale applications. However, for the storage of huge and very huge quantities of energy which is the most important aspect for the use of renewable energies, (lignin based) organic flow batteries are less costly and in addition more sustainable regarding the use of resources. Their operation is more secure and stable. No problematic raw materials are used. Supply bottlenecks and cost explosions are not expected. The disposal is ecological, as most of the components are easily recycled and as no problematic waste products are generated.

Showcase 9: Breakthrough for sustainable aviation fuel from lignin

Sustainable aviation fuel (SAF) is essential to decrease the carbon footprint of the aviation industry. Although many strategies have been developed to provide the linear and branched aliphatic components of SAF, few viable strategies have been demonstrated to supply the aromatic and cycloalkane fraction of the SAF at the necessary scale from bio-based feedstocks. A team in the U.S.A. has successfully addressed this challenge by developing a process that is based on a commonly occurring catalyst.

The team involving the National Renewable Energy Laboratory (NREL), the Massachusetts Institute of Technology (MIT), and Washington State University uses lignin for the production of the SAF. The two main challenges are finding an effective catalyst and to remove the oxygen from the lignin. The lignin oils in existing research projects had an oxygen content of 27 to 34 %. For aviation fuel, however, this value has to be lower than 0.5 %. Until now catalysts were used that contained expensive precious metals which in addition showed only low efficiency.

The successful new approach consists of a continuous, two-stage catalytic process using molybdenum carbide to deoxygenate lignin into aromatic hydrocarbons with 87.5% selectivity toward aromatic hydrocarbons at 86% of the theoretical carbon recovery. Tier α fuel property testing indicates that the SAF-range lignin-derived aromatic compounds are likely performance-advantaged across multiple properties relative to conventional jet fuel aromatic compounds. This work demonstrates an effective approach to converting lignin into aromatic SAF blendstocks.

The team has published its process in the journal “Joule” (Continuous hydrodeoxygenation of lignin to jet-range aromatic hydrocarbons - ScienceDirect). In the paper, the necessity of using SAFs is highlighted, as the aviation industry has engaged in a drastic reduction of carbon dioxide emissions. At the same time, the consumption of aviation fuels is strongly growing. It is said that the reduction of carbon dioxide emissions can only be achieved with the massive use of SAFs.

Showcase 10: Lignosulfonates as an example of lignin marketing

Lignosulfonates (LS), water-soluble anionic polymers derived from lignin during the sulfite pulping process, have been successfully marketed for almost a century. More than 1 million tons of this product are sold every year. Their commercial success is largely due to their low cost, biodegradability, and versatile functional properties, including dispersing, binding, complexing, and emulsifying abilities. These characteristics make LS an attractive ingredient across a wide range of industries.

One of the largest markets for lignosulfonates is the construction sector, where they serve as water reducers and plasticizers in concrete formulations. By improving the workability and strength of concrete while reducing water content, LS contribute to cost savings and enhanced durability in building materials. In the feed industry, lignosulfonates are widely used as pellet binders. They enhance pellet durability and cohesion, reducing dust formation and improving the transportability of feed. This improves feed efficiency and helps ensure uniform nutrition intake for livestock. In agriculture, LS act as dispersing agents in pesticide and fertilizer formulations, ensuring even nutrient or chemical distribution. This improves the efficiency of agricultural treatments while reducing environmental impact.

Lignosulfonates also play an important role in dust suppression, particularly for unpaved roads, mining operations, and storage piles. Their ability to bind fine particles reduces airborne dust, improving air quality and working conditions in industrial and transportation settings. In the oil and gas industry, LS function as dispersants and stabilizers in drilling muds, helping to prevent clumping of solids and improve fluid stability under high-temperature and high-pressure conditions. This enhances drilling efficiency and reduces operational costs.

Beyond these applications, lignosulfonates are used in various industrial processes, such as leather tanning, dye dispersing in textiles, and adhesives. Their ability to bind, disperse, and stabilize compounds makes them useful in coatings, resins, and industrial binders. With increasing demand for sustainable and cost-effective solutions, lignosulfonates continue to be a key bio-based ingredient across multiple industries. Ongoing research into high-value applications, including biopolymers, pharmaceuticals, and environmental remediation, suggests that new markets could emerge in the near future.

Showcase 11: Sulfonated Kraft lignins as a high-value port-folio

Ingevity, formerly known as Westvaco, has been successfully marketing sulfonated Kraft lignins (SKL) as high-performance dispersants and emulsifiers for over 70 years. With a focus on high-value applications rather than bulk commodity markets, the company has established itself as a global leader in Kraft-lignin-based specialty chemicals. Today, Ingevity markets a significant volume of lignin annually, supplying industries in North America, Europe, and Asia with innovative and sustainable solutions.

One of the company’s most significant markets is the dye and pigment industry, where SKL serves as an effective dispersant in water-based formulations. By preventing particle agglomeration, Ingevity’s dispersants enable stable and uniform color distribution in textile dyes, printing inks, and coatings. These lignin-based dispersants offer excellent performance at a competitive cost, while also providing an environmentally friendly alternative to synthetic dispersants. Over the decades, Ingevity has built strong relationships with leading dye manufacturers across the U.S., Europe, and Asia, making this its largest and most successful application.

In the agrochemical sector, Ingevity’s SKL dispersants play a key role in herbicide and pesticide formulations, ensuring even suspension and distribution of active ingredients in water-based solutions. This enhances efficacy, reduces sedimentation, and improves application efficiency, particularly in large-scale farming operations in North and South America. The company has long been a trusted supplier to major agrochemical manufacturers, helping to meet the industry’s growing demand for bio-based and biodegradable additives.

Another well-established application is in asphalt emulsions for road construction and maintenance. Ingevity’s lignin-based emulsifiers help stabilize bitumen-water mixtures, leading to longer-lasting, cost-effective, and environmentally friendly pavement solutions. Widely adopted in North America and Europe, these products contribute to improved road durability and reduced maintenance costs, aligning with governmental sustainability initiatives.

Unlike some lignin producers that target low-value bulk markets such as concrete admixtures or oil and gas, Ingevity has maintained a high-margin portfolio focused on specialty chemicals. The company’s success is driven by continuous innovation, strong customer relationships, and decades of expertise in lignin chemistry. With an annual global market presence in the tens of thousands of tons, Ingevity remains at the forefront of expanding the industrial applications of sulfonated Kraft lignins, proving their value as functional, cost-effective, and sustainable dispersants and emulsifiers.

THIS PAGE IS UNDER CONSTRUCTION

MORE SHOWCASES WILL BE POSTED SOON

If you want to submit a showcase you can do so by sending an email to